Product Summary

The dynaplaque Maxidyn performs tests to standard NF P94-117-2 to measure platform bearing capacity from 20 MPa to 250 MPa.

The advantages of Dynaplaque Maxidyn

Precision

High efficiency

Carrier choice

The advantages : Dynaplaque Maxidyn

Simplified installation

on your single-cab 4×4 without complex chassis modifications

Choice of dispensing system

of the loading plate. Forklift or crane carrier.

Test report generation

by the acquisition software.

Three-year warranty

The ball and the removal system (fork or crane) are guaranteed for parts and labor.

36 months.

High performance

The equipment can perform several dozen tests per hour without leaving the vehicle, and can be used by a single operator.

Intuitive software

The acquisition and export software is designed for touchscreen use on a rugged Windows laptop.

Responsive after-sales service

Our service workshop in Courcouronnes (Ile de France) guarantees fast, efficient after-sales service.

A validated solution

The Maxidyn dynaplate is validated and checked every year on a test bench in accordance with the specifications of standard NFP 94-117-2.

For further details

Boulet dynaplaque Maxidyn

Fork carrier

Crane carrier

Installation on the carrier

Driver's cab

Software

Boulet Maxidyn

The Maxidyn ball is fully compliant with the NFP 94-117-2 standard “Modulus under dynamic Dynaplaque loading”.

The 150kg drop-weight falls 40cm onto a 600mm load plate to produce a 70kN impact on the ground. Ground displacement is then measured using an accelerometer.

The ball and its sensors are checked annually on calibration benches connected to national standards.

Hydraulic system

The hydraulic system is driven by a pump located on the carrier’s accessory belt.

Pump management is automatic. The pump is activated by pressing a movement button on the wired remote control inside the cab. Without further control, the pump switches off after 15 seconds or if the driver removes the handbrake.

In case of emergency, a manual pump is available at the rear to retract the fetlock.

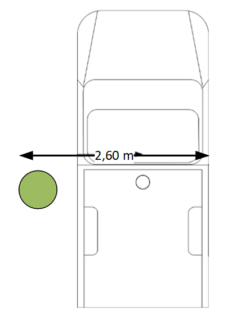

Deposit zone

The ball is removed from the driver’s side. Once removed, the vehicle’s overall width is less than 2.70m.

The hydraulic fork allows the ball and chain to be lowered to between -10 and -20 cm below wheel level. A system of extensions consisting of two metal bars attached to the end of the fork allows you to descend to -80cm.

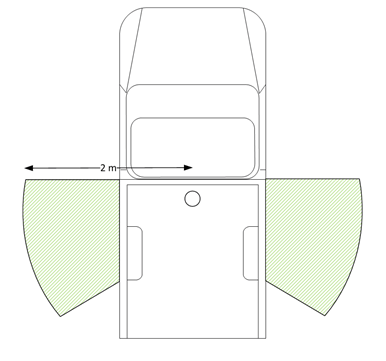

Door installation

Ford Ranger pickups can be installed on a force-type carrier. Other types of carrier are subject to validation by our technical department.

The ball is lowered in a single movement by two cylinders on its sides.

Hydraulic arm

The hooking chains are designed to allow rapid removal of the plate whatever the configuration of the site (slope, large overhang, downhill, etc.).

The loading plate is manipulated by the operator using the hydraulic arm’s wireless remote control. The operator is either a holder of the CACES (R390) Grue Auxiliaire de Chargement de Véhicule (GACV) or a driving license.

Deposit zone

The hydraulic arm enables the ball to be lowered to a depth of between -50 cm and -80 cm, depending on the chosen carrier.

Extended ball attachment

The ball is held on the side of the carrier between two measuring points by a hook attached to the body.

So there’s no need to put the ball back in the bucket between two measurements. A simple lift of the ball allows it to be hooked in, avoiding any swinging while the vehicle is in motion.

Carrier

The equipment is installed on the carrier in our laboratory in Courcouronnes (Ile de France).

Changing the carrier can be carried out at reduced cost, for example during annual maintenance.

Driver’s cab

The software can be installed on any Bluetooth-enabled Windows laptop.

For optimum use, we recommend an 8″ or 10″ touchscreen tablet mounted on the passenger side. The supply, installation and configuration of this tablet is included in our price offers.

This tablet allows :

- Use of equipment inside and outside the vehicle.

- Retrieve GPS maps and transmit the report to your 3G/4G phone.444

- Produce reports immediately on site.

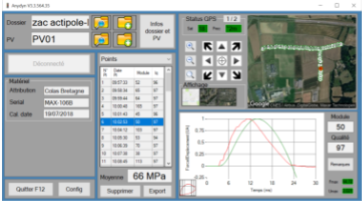

Acquisition and reporting

The Maxidyn dynaplate is controlled by the Anydyn acquisition and reporting software (developed by Rincent Nd Technologies) and is supplied with the equipment.

The software interface is designed for rapid testing:

- A single interface for testing.

- Large buttons for tactile operation.

- Intuitive to use, 3 steps are all it takes to carry out a measurement (create a file, then a report and run a test).

Software installation

A login is provided to access the download page of the Rincent ND Technologies website.

Software can be installed freely on an unlimited number of PCs.

Software updates are free and available for an unlimited period.

As the Maxidyn calibration data is contained in the hardware, there is no software configuration to be carried out: this facilitates computer replacement.

Photos of equipment

Downloadable documents